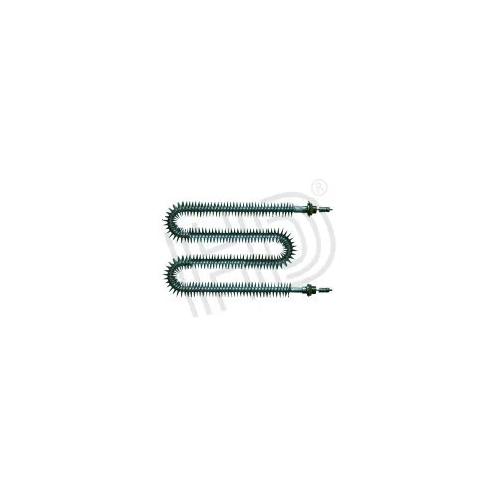

Papercup Machine Heater

Price 4400 INR/ Piece

Papercup Machine Heater Specification

- Usage & Applications

- Heating element for papercup forming machines

- Type

- Papercup Machine Heater

- Material

- Stainless Steel & Ceramic

- Capacity

- Continuous Heating

- Voltage

- 220 V

- Power

- 800 W

- Power Source

- Electric

- Input Voltage

- 220 V

- Output Voltage

- 220 V

- Installation Type

- Bolt-On

- Dimension (L*W*H)

- 180mm x 80mm x 40mm

- Weight (kg)

- 0.92

- Color

- Silver

- Compatible Machines

- Automatic and semi-automatic papercup machines

- Protection Feature

- Overheat protection

- Lead Wire Length

- 1 meter

- Thermal Insulation

- Yes

- Maximum Operating Temperature

- 450°C

- Resistance Tolerance

- ±5%

- Heating Element Material

- High-grade nickel-chromium

- Service Life

- Up to 7000 hours

- Ambient Temperature Range

- 0°C to 60°C

- Mounting Method

- Pre-drilled flange

Papercup Machine Heater Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- CE

About Papercup Machine Heater

Consistent Performance for Paper Cup Machines

Engineered with a high-grade nickel-chromium heating element, the Papercup Machine Heater delivers stable and efficient heating suitable for intensive manufacturing environments. Its maximum operating temperature of 450C and robust 800 W power output guarantee fast and reliable results in both automatic and semi-automatic papercup forming machines.

Durability and Safety Features

Constructed from stainless steel and ceramic, this heater offers excellent resistance to wear and corrosion. The integrated overheat protection and comprehensive thermal insulation ensure safe operation, even during continuous, extended use. A pre-drilled flange and bolt-on installation design make fitting simple and secure.

Extended Lifespan and Broad Compatibility

Benefit from a service life of up to 7000 hours and compatibility with various papercup machine models. The 1-meter lead wire provides flexibility in installation, while the heater maintains top performance within ambient temperatures ranging from 0C to 60C, accommodating most production settings.

FAQ's of Papercup Machine Heater:

Q: How is the Papercup Machine Heater installed in papercup forming machines?

A: The heater is easily installed using a pre-drilled flange and bolt-on method, ensuring a secure fit in both automatic and semi-automatic papercup machines. The 1-meter lead wire allows for flexible positioning during setup.Q: What benefits does the high-grade nickel-chromium heating element provide?

A: Nickel-chromium offers superior heat conductivity, enabling rapid and uniform heat generation up to 450C. This material also resists oxidation and thermal degradation, ensuring reliable performance and a longer lifespan.Q: When should the Papercup Machine Heater be replaced?

A: With a service life of up to 7000 hours, the heater should be inspected regularly for wear or performance decline. Replacement is recommended if the heater fails to reach set temperatures or shows signs of overheating, to maintain production efficiency and safety.Q: Where is this heater suitable for usage and who can benefit from it?

A: Designed for use in papercup forming machines, the heater is ideal for manufacturers, suppliers, exporters, and distributors operating in India or similar markets, seeking a durable and efficient heating solution.Q: What is the process for ensuring safe operation of the heater?

A: The heater includes overheat protection and comprehensive thermal insulation to prevent damage and safety hazards. It is recommended to follow the manufacturer's installation and operation guidelines for optimum performance and security.Q: How does the heater accommodate various machine types and installation environments?

A: This heater is compatible with both automatic and semi-automatic papercup machines, thanks to its standard 220 V input/output, bolt-on installation, and wide ambient operating range from 0C to 60C.Q: What are the distinct features that make this heater reliable for continuous operation?

A: Key features such as thermal insulation, overheat protection, resistance tolerance of 5%, and durable construction ensure the heater is well-suited for continuous, uninterrupted use in rigorous production settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Heaters Category

U Type Air Heater

Price 400 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 500 W 5 kW

Material : Other

Voltage : 220 V / 230 V

Dimension (L*W*H) : Varies (customized as per requirement)

Bth Type Air Heater

Minimum Order Quantity : 6 Pieces

Power : 3 kW

Material : Stainless Steel

Voltage : 220 V

Dimension (L*W*H) : Customized

M Type Air Heater

Price 500.0 INR / Piece

Minimum Order Quantity : 6 Pieces

Power : 250 Watt (w)

Material : Stainless Steel

Voltage : 230 Volt (v)

Dimension (L*W*H) : As per requirement Meter (m)

PORCELAIN HEATER

Price 2800 INR / Piece

Minimum Order Quantity : 1 Piece

Power : 250W 2000W (as per model)

Material : Other, Highgrade Porcelain and Nichrome Wire

Voltage : 220V to 240V

Dimension (L*W*H) : Standard/Custom sizes available

|

HEATING DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry